TN EQUIPMENTS

Technology

FIBER LASER CUTTING MACHINE

Fiber Laser Cutting Machine is used to cut materials such as metals, PVC plastic screens, and many other types of materials. It uses a super-thin laser beam to cut precisely and quickly, allowing the production of parts with high accuracy and lower cost than traditional cutting methods.

BENDING MACHINE

Stamping/forming is a popular method for shaping sheet metal in metalworking.

It is a process that applies a large force from above to press, stamp, squeeze, or cut metal products according to specific requirements. TN utilizes a range of single-axis press machines from the renowned brand AMADA, enabling easy and highly precise machining operations, suitable for mass production. With their experienced technical team, TN can support development and mold design, ensuring that the produced items meet the required specifications and maintain consistent quality.

Equipped with modern facilities and a team of skilled workers with years of experience, TN guarantees to deliver high-quality metal stamping/forming products and excellent services to its customers in the market.

AMADA

CNC metal hole machining is a process that utilizes specialized punching machines to apply force on the surface of a metal blank or material to create holes with different shapes and sizes.

At TN, we use the AMADA machine series, which provides a punching force of 33 tons, and operates fully automatically for the machining process. The hole punching machine is controlled through automated software by our experienced team of technicians. This is a continuous and automated process that helps save costs and time compared to other traditional machining methods in the market.

WELDING ROBOT

At TN, we provide welding solutions such as MIG welding, TIG welding, resistance welding, and robotic welding for OEM projects, consumer products, and various supporting industries.

We have a team of extensively trained personnel who are well-versed in the latest welding technologies. They provide technical support throughout the product development phase to the completion of the final product. Additionally, our team possesses the capability to support automated production for manufacturing operations of all scales, from small to large.

ELECTROSTATIC POWDER COADTING

Electrostatic Powder Coating line according to AAMA 2603/04/05 standards is an automated system that carries out the process of electrostatic spray painting with multiple colors on metal or non-metal surfaces such as steel, aluminum, copper, zinc... The purpose is to create a uniform coating of paint with a thickness ranging from 60-90 micrometers, which is durable and protects the surface from abrasion, oxidation, and corrosion.

Electrostatic Powder Coating, when applied in sheet metal processing, provides high durability, environmental friendliness, and maintains a smooth and glossy finish. At TN, we have an automated electrophoretic coating line, enabling fast turnaround times and catering to a wide range of production scales, from single pieces to mass production.

THIEN NAM INDUSTRIAL

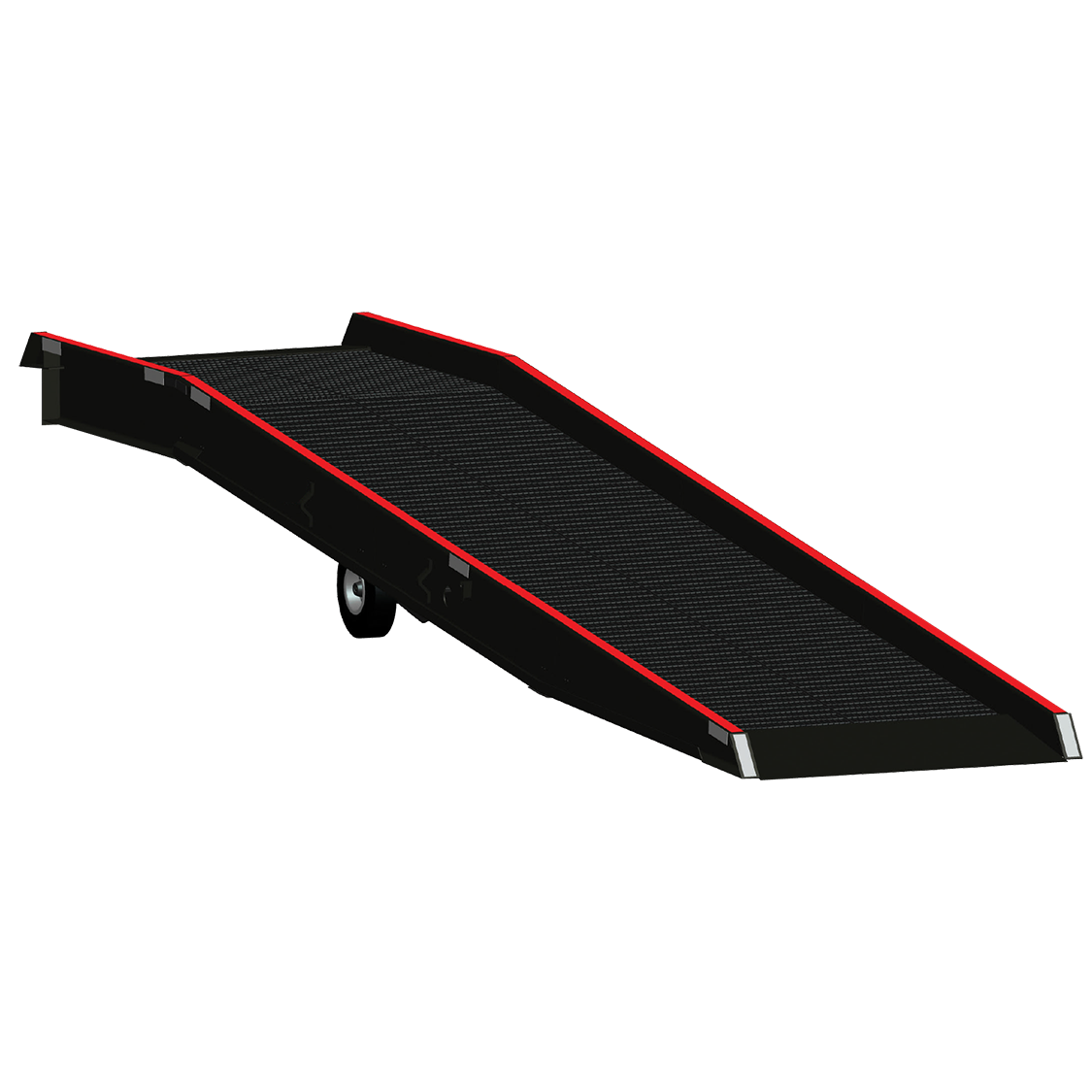

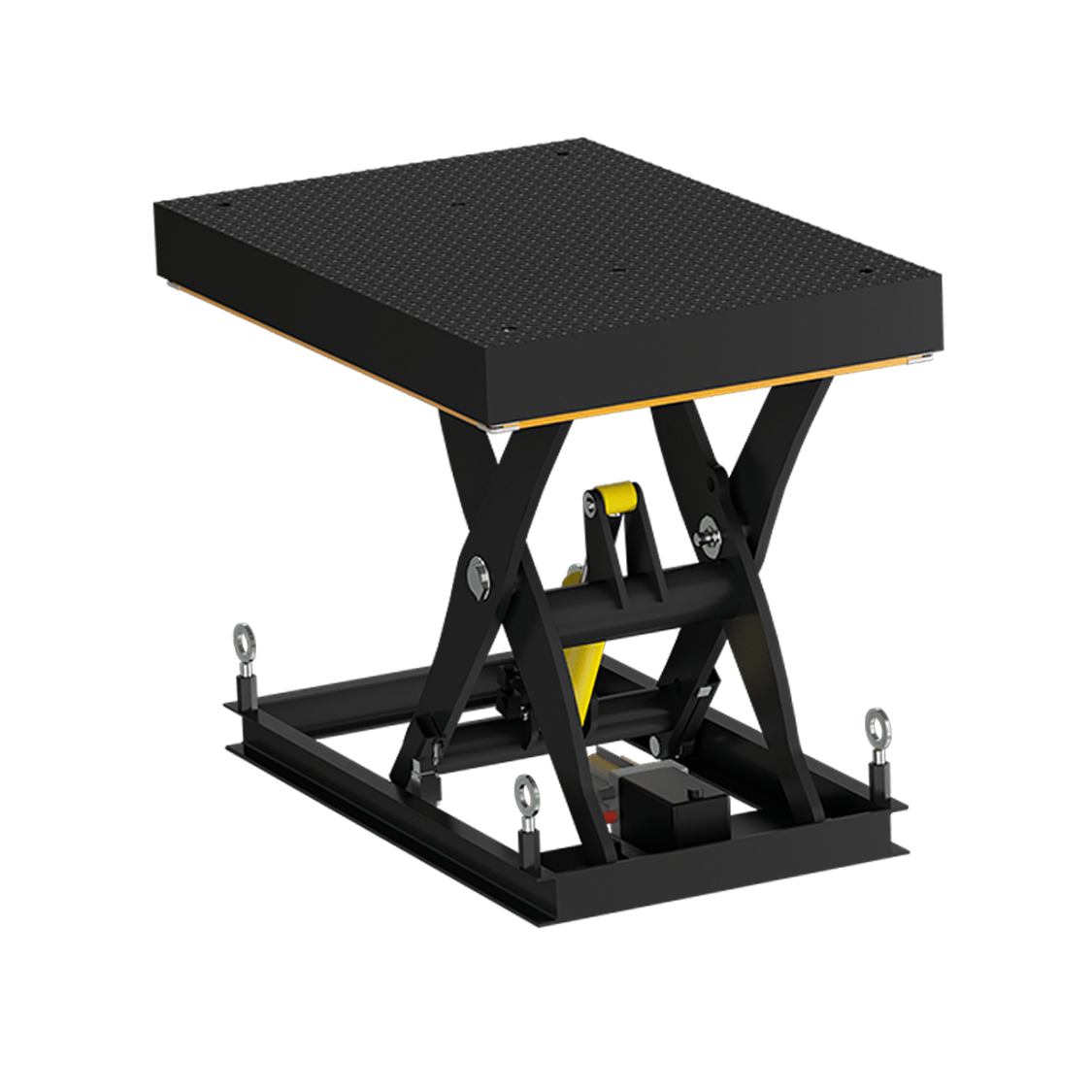

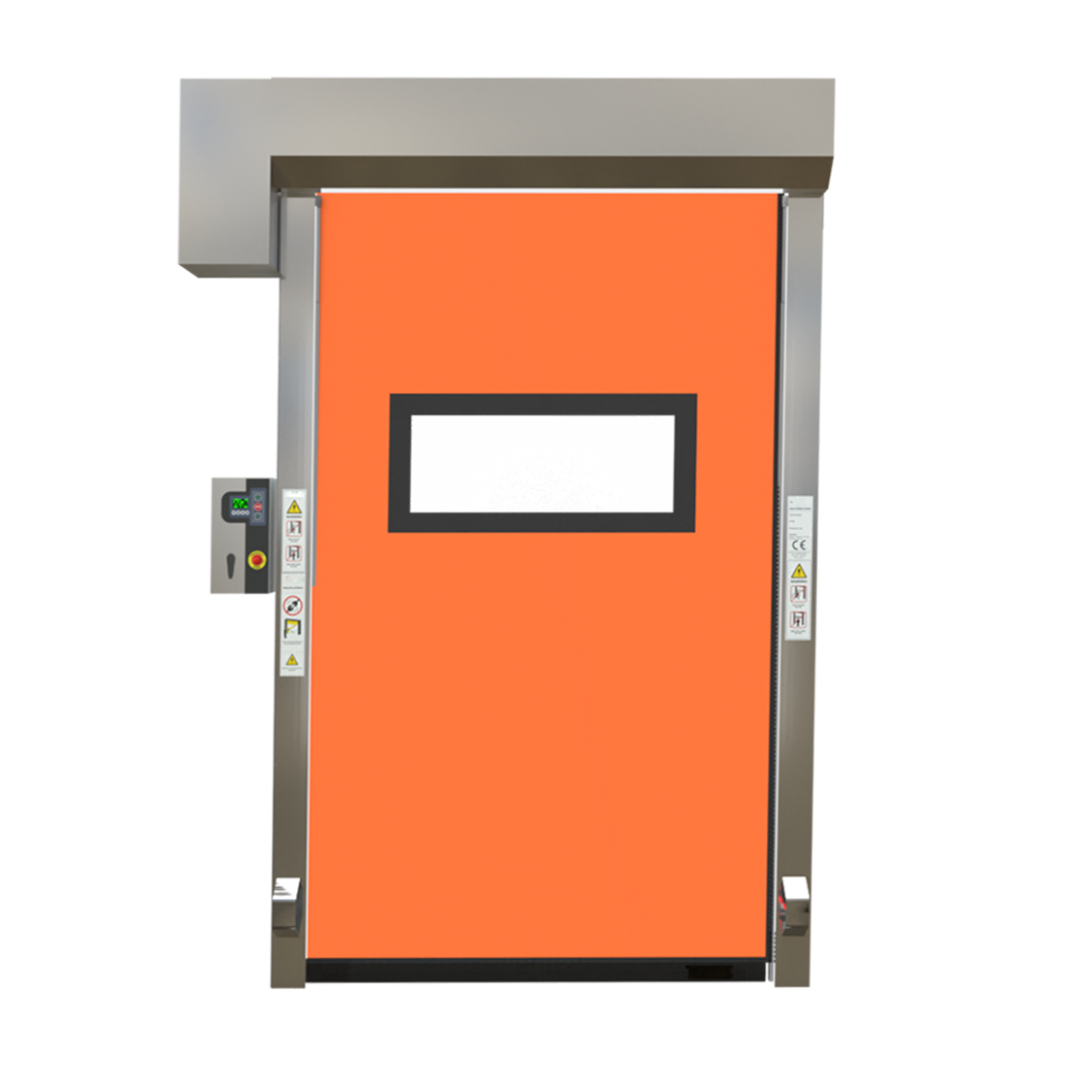

Products

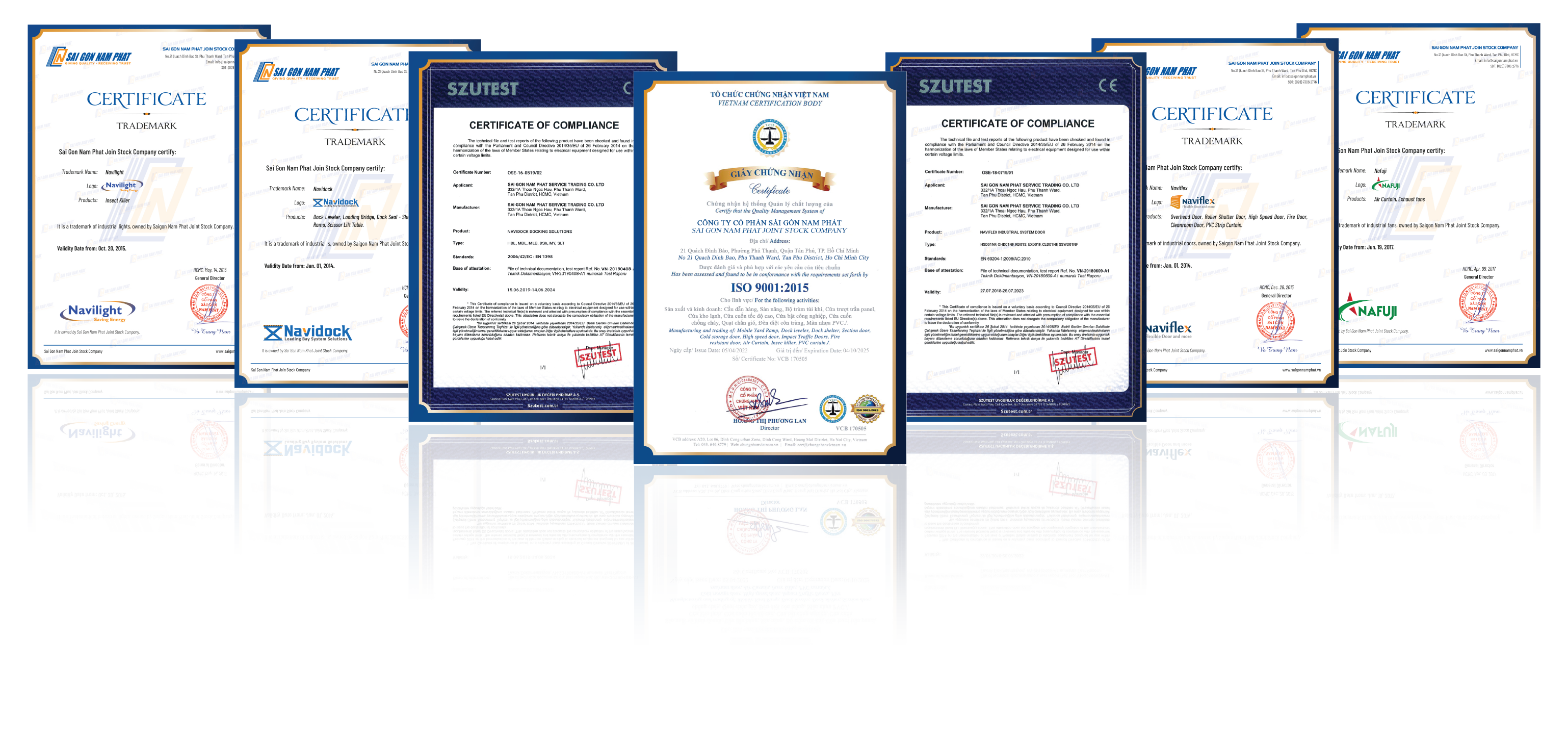

Certificates

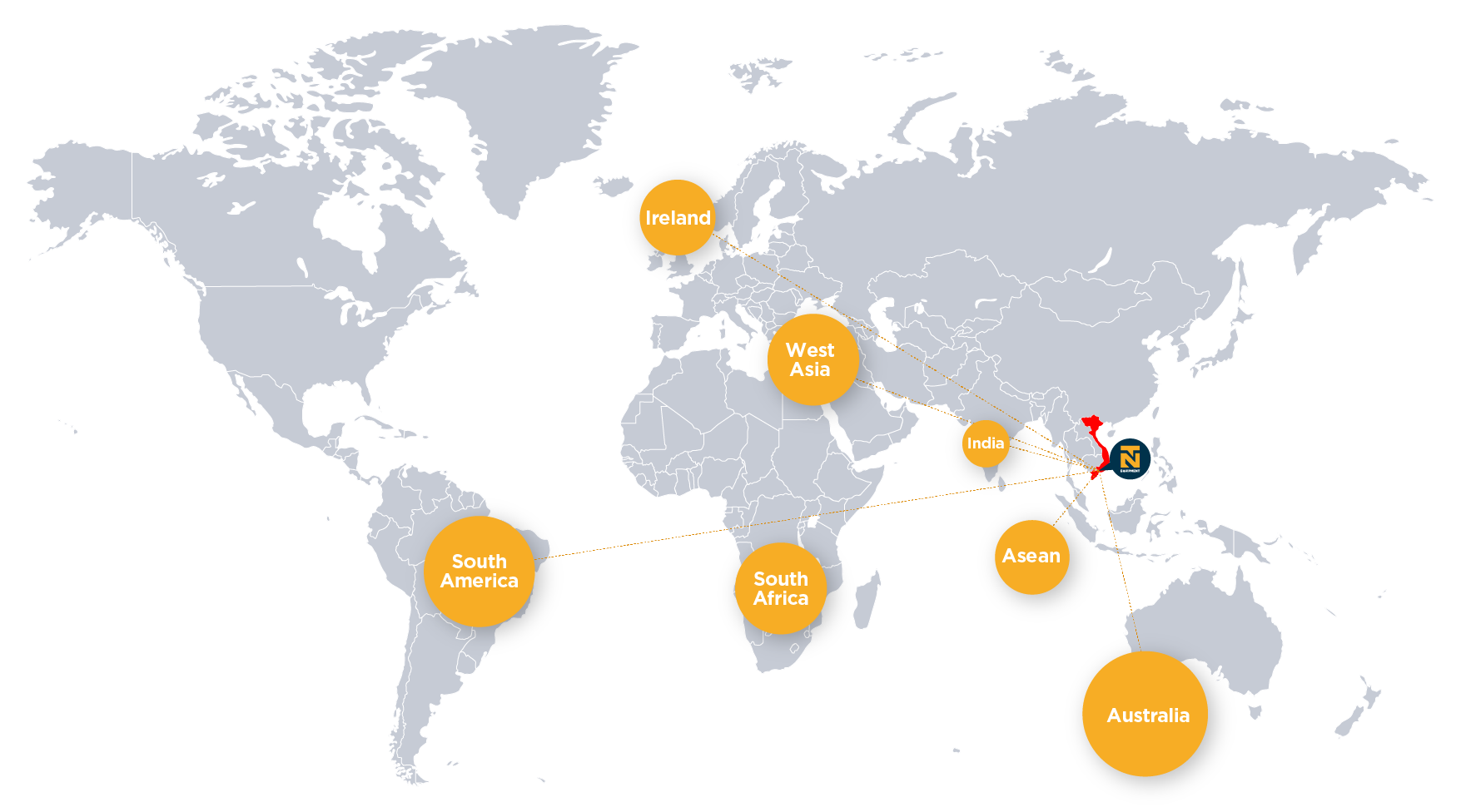

EXPORT